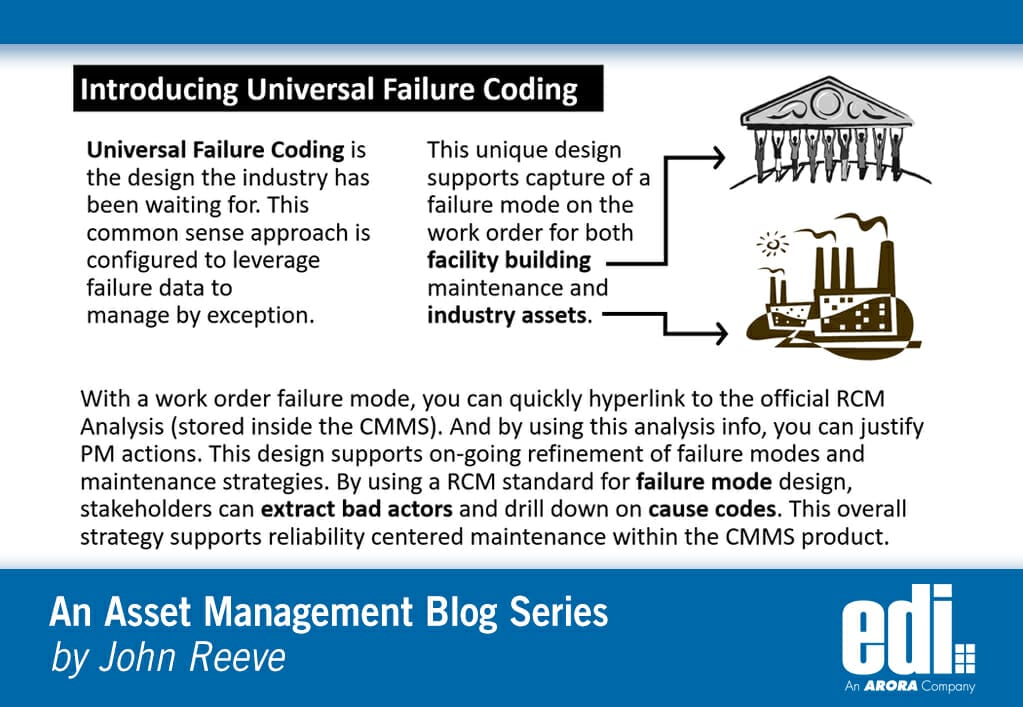

For many years, the CMMS community has stumbled over this design. Some user sites build failure code hierarchies that have over 20,000 boxes. Some believe failure codes should always be specific to the equipment classification, or failure class. Lastly, some are not familiar with the RCM standard SAE JA1011, where failure mode is clearly defined.

There are 3 Types of Assets

- System assets — are complex; can have close to a hundred components

- Simple assets — are basic in design; they have a short list of components that can fail (e.g. a Fire Door)

- Pseudo-Assets — are not real assets, but get worked on by Facility Maintenance (e.g. a regular door)

The above categorization is used to determine the component list. And the good news is, there is absolutely no reason why you cannot capture the failed component on all 3 types.

Key Design Elements

- Maintenance is performed at the component level.

- Failure code is not the same as failure mode.

- It is not necessary to store Cause and Remedy at the bottom of a Failure Code Hierarchy.

Procrastination

Some put this effort off until later due to its complexity. Thus, they may be operational for years and never have any failure data. This is very sad because it is rather hard to go back in time to recover this data (from narrative text fields).

The first step towards understanding this puzzle is to understand the different types of failure data. Some of it is structured (validated) and some is unstructured (text field). Both are needed for proper analysis; however, it is the failure mode that needs to be broken into 3 pieces:

- Failed component

- Component problem

- Cause code

The Failure Analytic is Based on What?

Speaking of analysis, the endgame is to make better decisions, not to build a hierarchy of codes. If you had thousands of assets, how do you know which one to focus on? How would you extract a bad actor list programmatically? I’ve listed some ideas below:

Extract those assets which have had

- the most repair work performed, or

- the highest cost to the asset, or

- the most downtime, or

- the smallest MTBF, or

- asset criticality times asset condition

In other words, you need to think about the metric you will use to extract these bad actors. The metric I like the most is Average Annual Maintenance Cost divided by Replacement Cost. Once you get a top 10 list, then you need to be able to drill down on cause.

There is one type of failure analysis that offers the greatest impact to reducing O&M costs. And that is shown in this picture. This design is further described in my book, Failure Modes to Failure Codes.

In addition, I am willing to visit your site to explain in detail exactly how this advanced design is implemented, or you can attend MaximoWorld 2019 and the 3-hour short course on Demanding Excellence from your Asset Management System.