NEWS AND INSIGHT

Categories

Tags

Recent Posts

Top Considerations to Accelerate Digital Transformation and Optimize Operations

Arora Engineers (Arora) and its subsidiary company EDI were recently featured in the January 2023 issue of Passenger Terminal World Magazine. Our team of asset data experts compiled their top considerations for the implementation of IT for Airports looking to accelerate digital transformation and optimize operations. Overall, the most important thing for airports to consider is that technology alone is rarely ever the full solution. Our experts advise that organizations need to look at the underlying business processes associated with the new technology to allow the investment to thrive.

Check out our tips to help your organizations accelerate digital transformations and optimize operations:

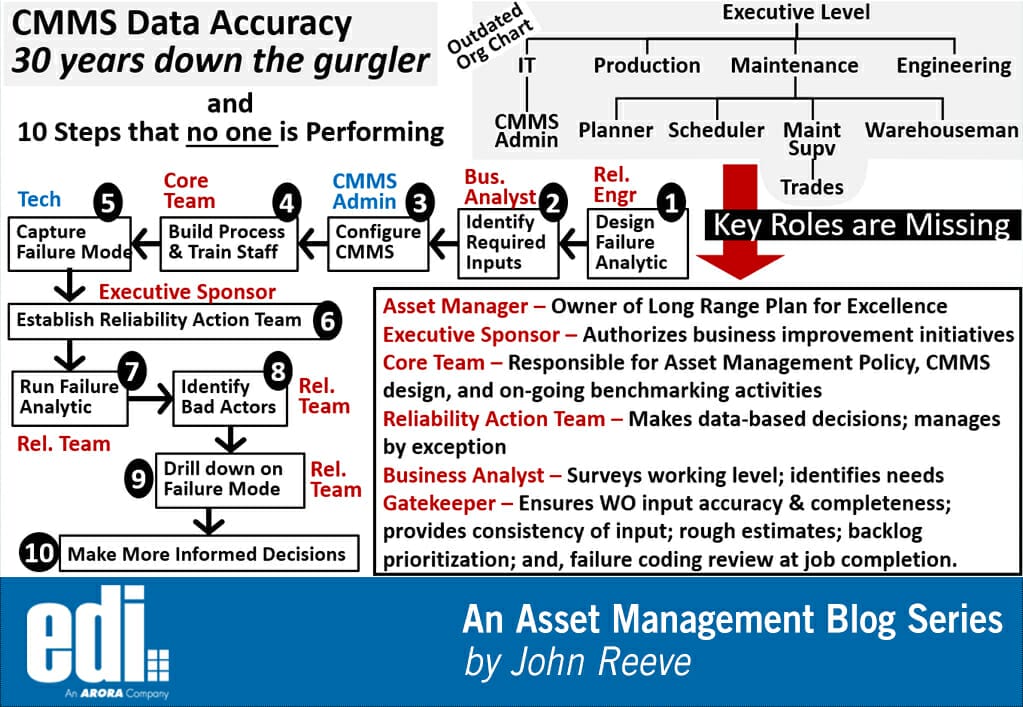

1. Start with an audit of the data you are already collecting. Organizations should look to see if your organization utilizes robust enterprise asset management (EAM) software and/or collect geographic information system (GIS)/building information model (BIM)/asset data. To leverage the technologies necessary to optimize your operations and asset management, you need to start with an accurate, complete virtual representation of your physical facilities and systems.

2. Establish clear operational and reliability goals. Make clear what the priorities of the functions are you are trying to optimize, such as public safety, customer satisfaction, cost per take-off, etc. It is also key to define which critical systems have the greatest effect on those measures (airfield, baggage handling, HVAC, etc. By establishing these goals, you can lay the foundation and prioritize a roadmap for what you need to get in place for both immediate impact and continuous improvement.

3. Invest in your foundational data. Save time and money by establishing data interoperability standards that de-silo your data in the capital development phase. This will allow it to be used and deployed by multiple departments and advanced enterprise systems (enterprise resource planning, building management system, EAM, GIS, digital twin, predictive maintenance, augmented reality/virtual reality, etc). From there, you can carry these data standards throughout the lifecycle of your facility to ensure the technologies achieve the desired outcomes.

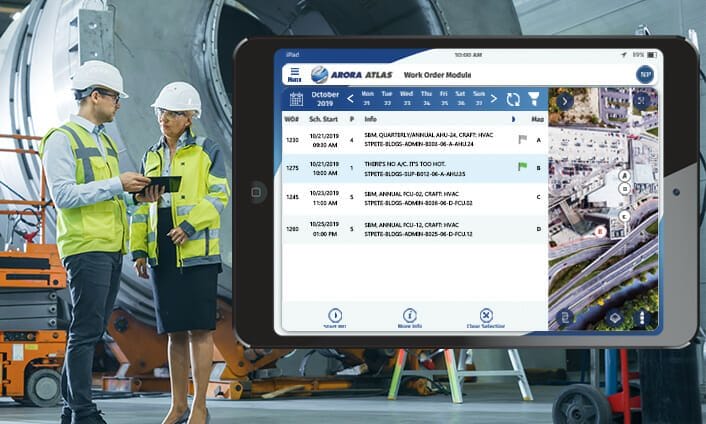

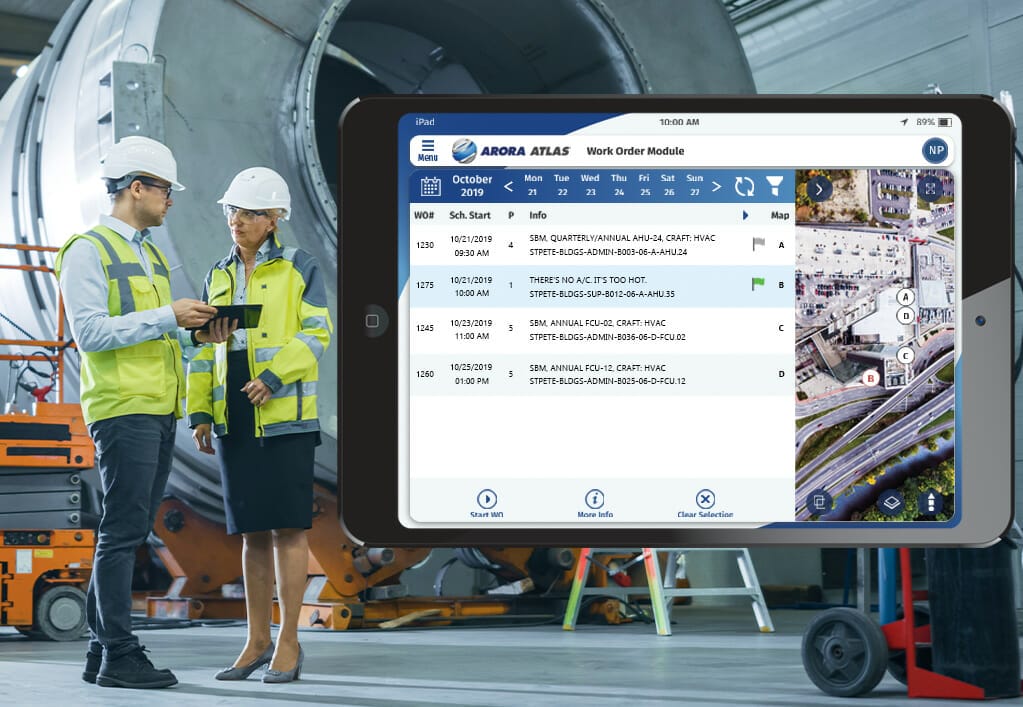

4. Maximize the value and efficiency of your assets by implementing an easy-to-use mobile solution like Arora ATLAS. This is an excellent tool for your technicians who are in the field performing and recording critical maintenance activities and inspections on the go. This data helps reduce operational expenses, streamline a single business process across all departments and improve the experience of technicians and airport guests alike.

Arora’s Enterprise Solutions Group specializes in business process consulting, the most essential element of any innovative technology deployment, to help its clients figure out how they will use the new technology and data collected to improve passenger experience outcomes. Contact us today to learn more!

To read the full article, click here.