NEWS AND INSIGHT

Categories

Tags

Recent Posts

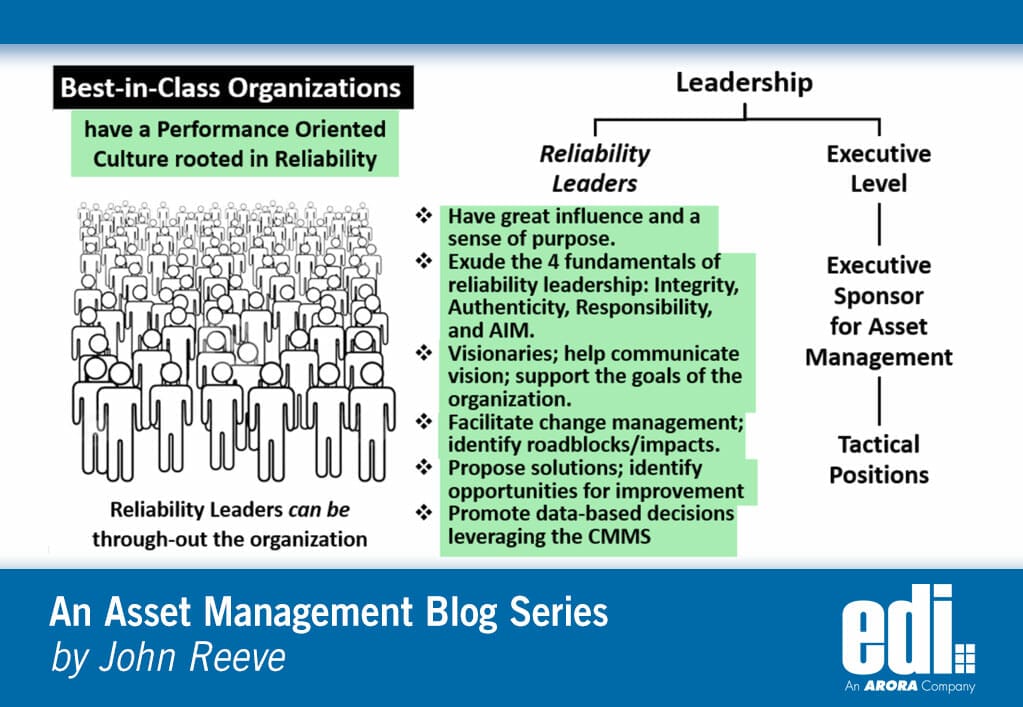

Reliability Leaders Can Be Everywhere

The 4 Principles of a Reliability Leader

- Integrity — Doing the right thing when no one else is around.

- Authenticity — Being who you say you are.

- Responsibility — Following through on assigned actions.

- Aim — Pursuing goals greater than one’s self.

The above is from a Reliability Web CRL study guide. The point to be made is that when talking about reliability it is not just an asset or equipment, rather it is also a person, at any level in the organization, who seeks continuous improvement in individual performance as well as process, role, and data.

Reliability Leaders Do the Following

- Perform regular benchmarking activities (search for knowledge).

- Acquire a common language for reliability through study.

- Create a declaration of reliability so that others know where you stand.

- Strive to take action to improve reliability.

- Support defect elimination.

- Help to empower others.

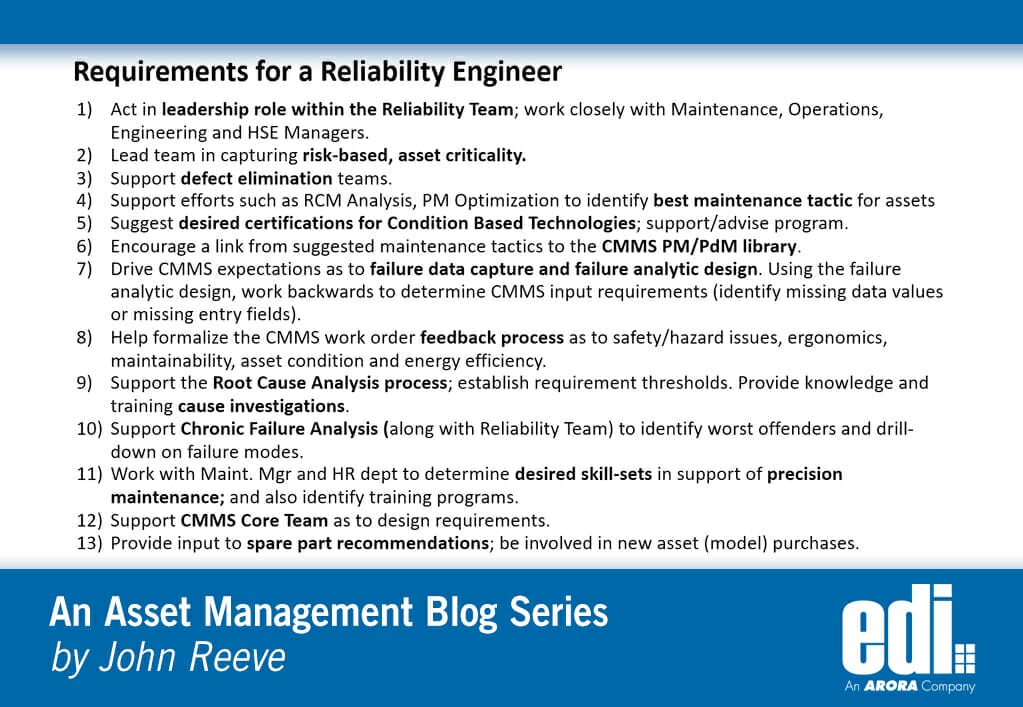

Example Roles Supporting Reliability

- Senior Management sets goals for performance, identifies RCA projects, and manages the long-range plan.

- Engineering is responsible for the design of (and often oversees the installation of) new equipment. Engineering also tracks asset performance, identifies likely failure modes, and tracks risk.

- Purchasing procures new equipment, which in turn, affects reliability.

- Storeroom staff contribute to equipment reliability by ensuring that proper parts are available, staged, and properly managed inside the storeroom. Critical parts are categorized, and standardized descriptions support search.

- Planners and schedulers focus on the right work at the right time based on criticality.

- Operators are trained to discover failure modes. They also perform minor maintenance tasks, including condition-based monitoring. Operators report emergency/urgent repairs, but otherwise adhere to the schedule.

- Maintenance staff perform scheduled work using the planned work instructions and adhere to job safety precautions. They also provide regular feedback at work order completion by updating the CMMS with accurate feedback regarding PM-job plan accuracy, asset maintainability, design flaws, ergonomic issues, safety hazards, and energy inefficiencies. Plus, they can provide overall asset condition updates on monthly PMs.

- The Reliability Action Team performs chronic failure analysis by extracting the top 10 worst performers using CMMS failure analytic.

- The Core Team manages the overall asset management information strategy by ensuring clear roles and processes, staff training, audits, and benchmarking activities. They ensure accurate data is in place to support analytical reports.

- The Business Analyst works closely with the Core Team to capture feedback, from working level, to minimize problems.