NEWS AND INSIGHT

Categories

Tags

Recent Posts

A CMMS Utilization Plan is Essential

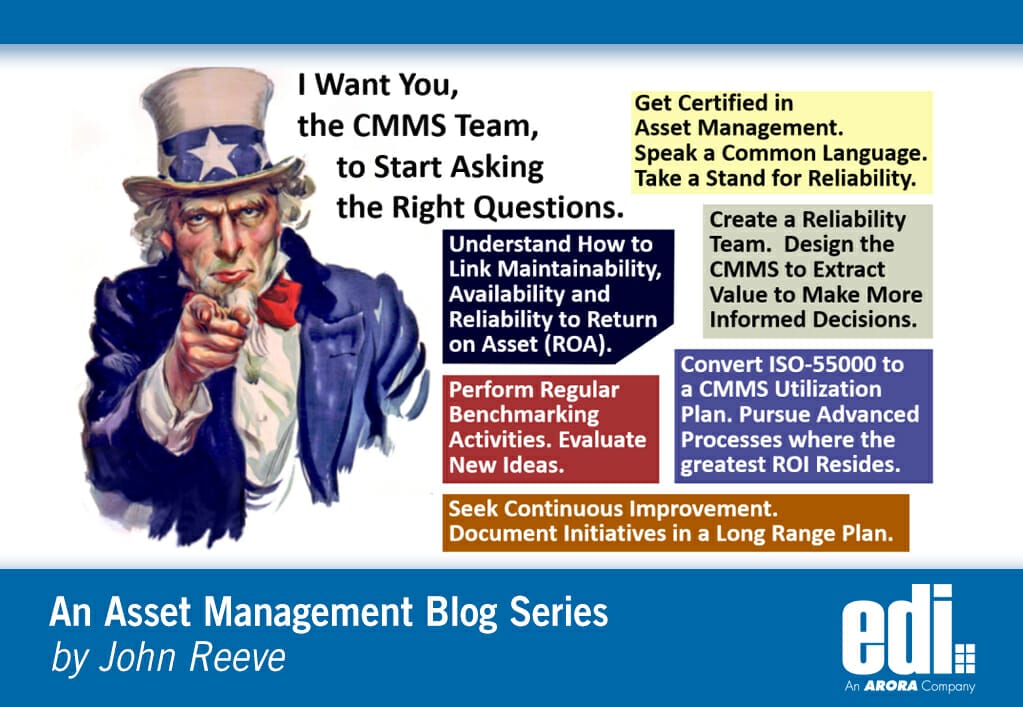

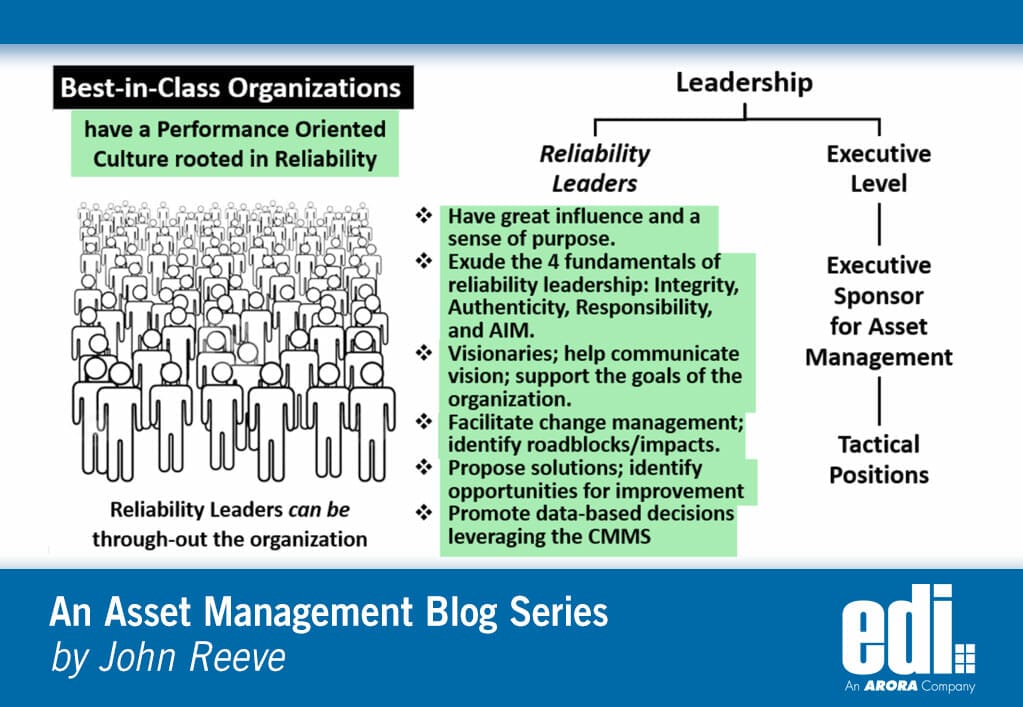

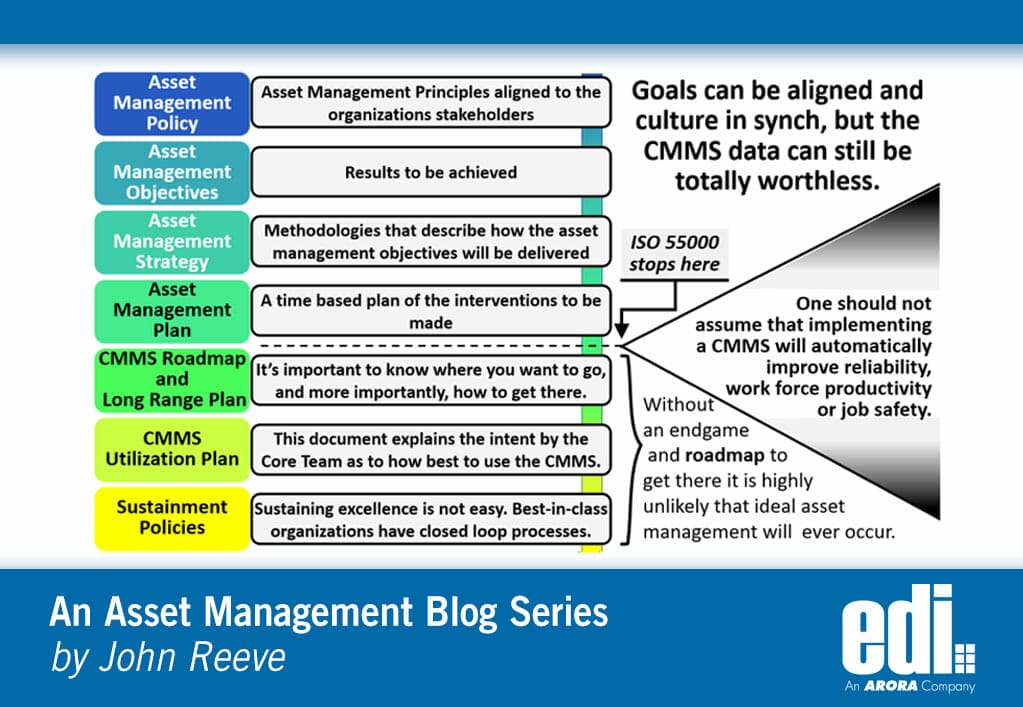

Many significant quotes come from ReliabilityWeb pertaining to asset management. The ISO-55000 standard is a key part of this roadmap. Some notable quotes are:

- Line of Sight is all about how an organization is organized around its core reason for being.

- Asset management is about applying engineering logic specifically to the ownership of physical assets.

- Brilliant asset management presents a clear line of sight.

But what if everyone does have a clear line of sight from the executive level down to the working level? Then what should happen? What results should we expect at that moment?

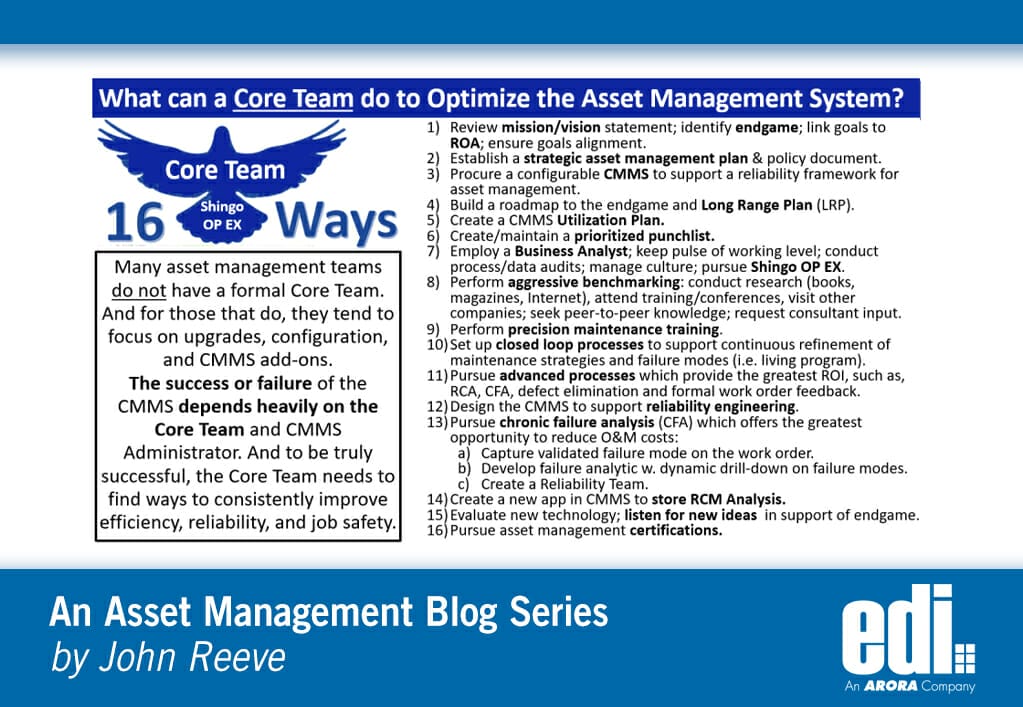

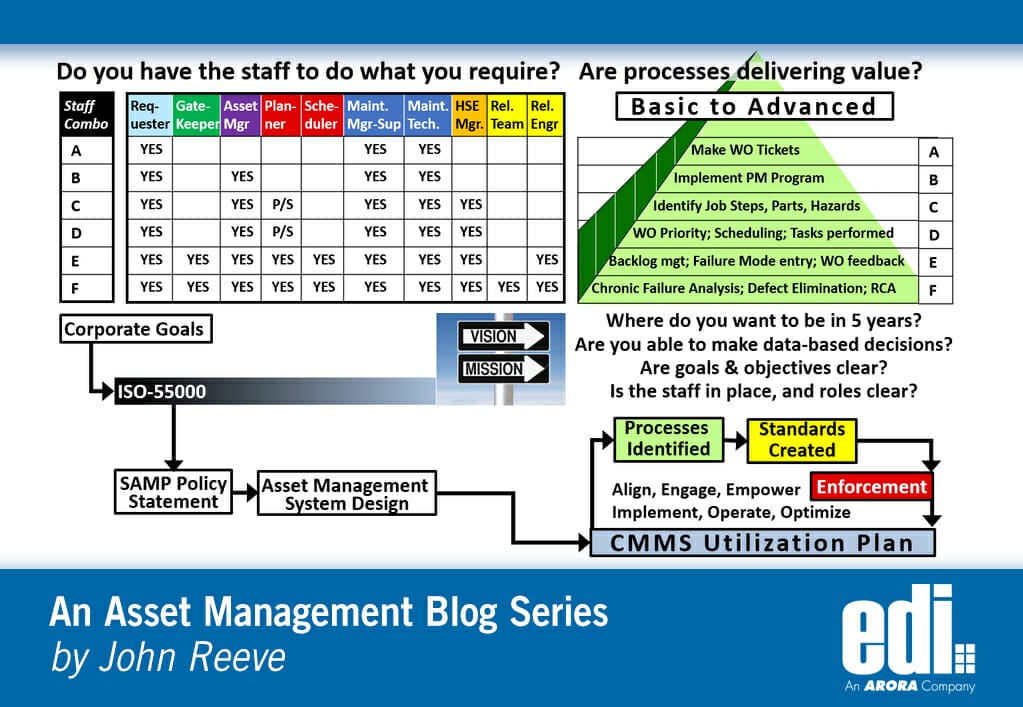

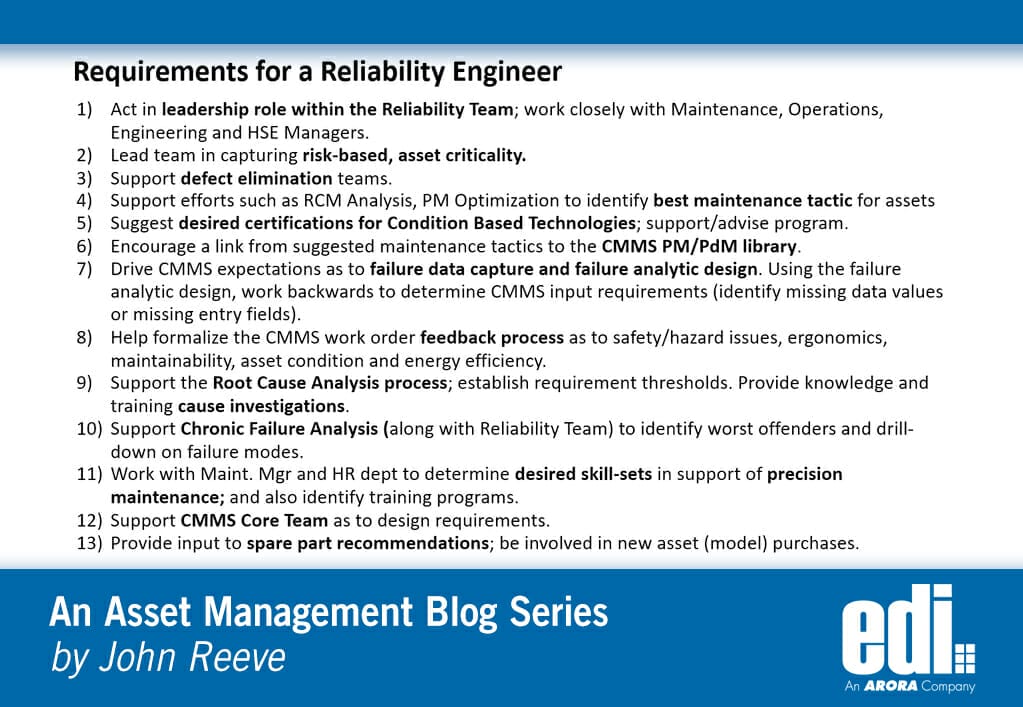

Software, Process, and Organization

The software may be world class, but the surrounding process is still critical. Even a best-of-breed CMMS product can be missing the necessary design elements to perform advanced processes essential to making more informed decisions. The Core Team needs to close these gaps. And without clear roles/responsibilities the data won’t be populated, making analytical reports impossible. And suddenly, we are back in the stone age.

Three Examples

Organization #1

The CMMS was embedded inside the ERP. The software implementation was focused around financial management. The project team lacked knowledge of asset management principles and practices. The asset portfolio was slim, no location hierarchy existed, and there was no inventory storeroom management in place. But the team knew how to install software and train users on screen navigation. At the end of the day, all they could do was capture costs against financial assets.

Organization #2

The CMMS team had 15-20 years of experience using the product. There wasn’t nothing they couldn’t configure (or customize). Unfortunately, this was an IT driven project, meaning no core team, no executive sponsor, and no reliability team. The working level and functional side were not involved and lacked buy-in. The CMMS team may attend venues to gain knowledge, but these were solely software related. 20 years later, still no failure data, or weekly schedule.

Organization #3

This organization had a core team with proper functional group representation. However, they performed little to no benchmarking. They didn’t really understand asset management, nor were there any certifications in reliability. They lacked knowledge in advanced processes where the greatest potential for return on investment resided. They relied primarily on the software vendor roadmap as to where time would be spent “massaging the product” and implementing new features. And they lacked a long-range plan which provided the shortest path to value.

A CMMS Utilization Plan Says What?

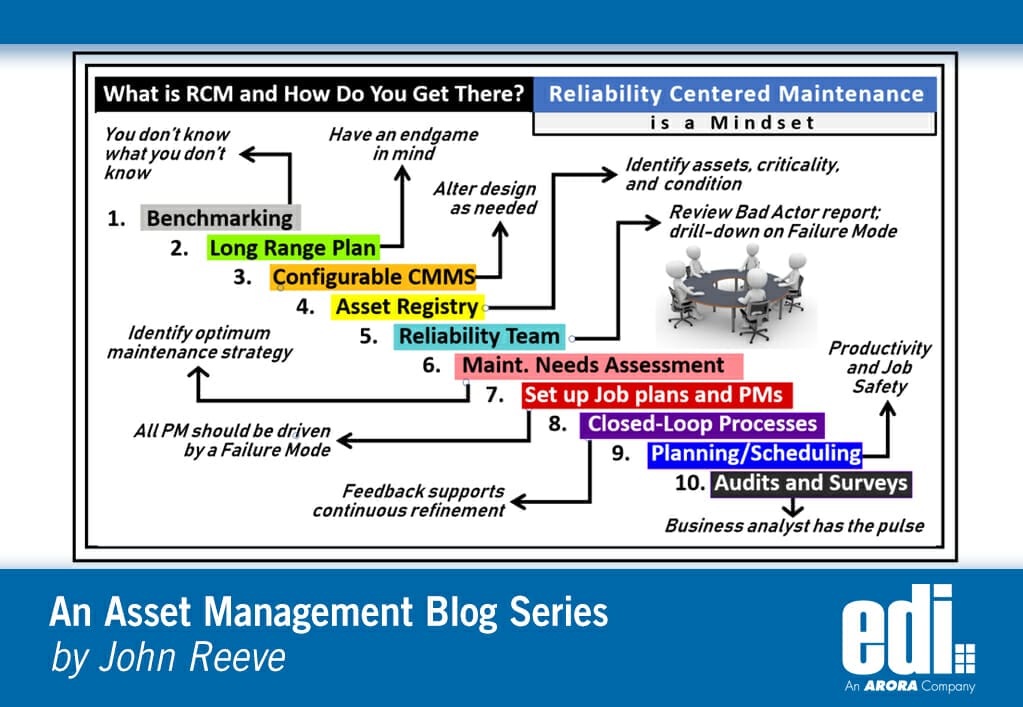

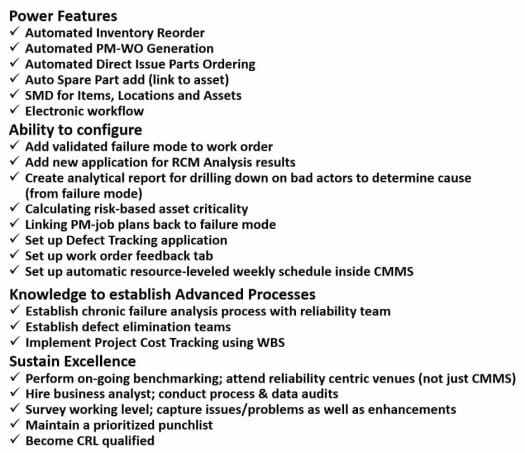

This document, created by the core team, states what advanced processes and power features will be implemented and used. The conversation starts with a roadmap on a whiteboard linking prerequisites to the endgame. These tasks are then transferred to a scheduling tool to establish durations, resource estimates, project assignments, and critical path. You may not get there over night, but that is the purpose of having a plan – to not forget what, why, and when. Example product goals might include:

Note that these goals are not just software related. There is also surrounding process and procedure. And from an organizational perspective, the business analyst role is all the more important if you plan to actually leverage any data to make more informed decisions. And in order to make real progress in the world of asset management, the benchmarking activity will be essential to support continuous improvement.